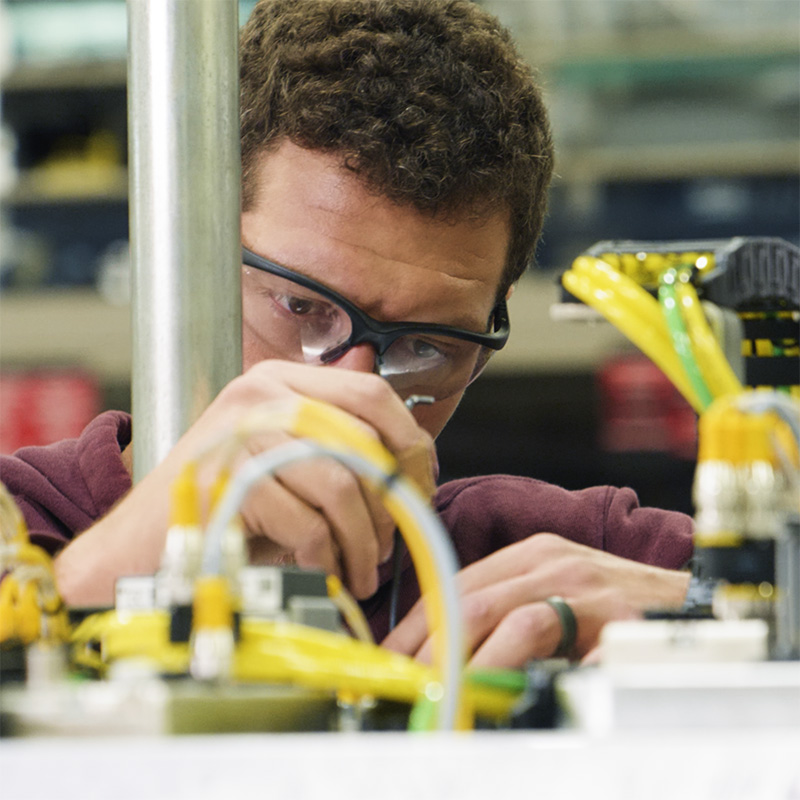

As vehicle designs become more advanced and materials continue to evolve, manufacturers are turning to innovative assembly methods that improve efficiency, quality, and sustainability. One technology leading this transformation is ultrasonic welding. At Hill Machinery Co., our US machine builders are proud to support the automotive industry with precision-engineered ultrasonic welding systems that meet the highest standards of performance and reliability.

What Is Ultrasonic Welding?

Ultrasonic welding is a solid-state joining process that uses high-frequency ultrasonic vibrations to bond materials together without the need for heat from an external source or additional adhesives. The vibrations create localized friction at the joining interface, generating enough energy to fuse materials—most commonly plastics or lightweight metals.

Since no melting or filler material is required, offers a clean, fast, and repeatable process ideal for high-volume production environments like automotive manufacturing. It has become a preferred method for joining plastic components, wire harnesses, electronic parts, and even select metal assemblies.

Improved Efficiency and Precision

Speed and accuracy are essential in the automotive industry, and ultrasonic welding delivers both. The process takes only seconds, allowing for rapid assembly without compromising quality. Automated control systems ensure consistent weld strength and precise placement, which helps reduce waste and rework.

In addition, ultrasonic welding eliminates the need for adhesives, fasteners, or curing time, making it more efficient than traditional methods. This not only streamlines the production process but also reduces material costs and the overall carbon footprint. By integrating advanced ultrasonic welding systems from our US automated machine manufacturer, automotive companies can achieve higher throughput and improved consistency across every part produced.

Enhanced Durability and Safety

Automotive components must withstand vibration, temperature changes, and constant stress. creates strong, hermetic bonds that resist mechanical and environmental challenges. In electrical applications, such as sensor housings or wiring harnesses, ultrasonic welding ensures reliable conductivity and secure insulation without the risk of contamination from adhesives.

The process also enhances vehicle safety by ensuring every joint is uniform and defect-free. This level of reliability is critical for safety-related components, such as airbags, sensors, and fuel system parts.

Supporting Lightweight and Sustainable Design

As the industry moves toward lighter, more energy-efficient vehicles, ultrasonic welding supports the use of advanced materials like composites and lightweight plastics. These materials are often difficult to bond using traditional welding or mechanical fastening methods. Ultrasonic welding provides an effective solution that maintains material integrity while reducing overall vehicle weight.

By making it easier to join dissimilar materials, ultrasonic welding contributes to improved fuel efficiency and helps manufacturers meet sustainability goals. It also aligns with the growing demand for electric vehicles, where lightweight design and precision assembly are essential for optimizing battery performance and range.

Shaping the Future of Automotive Manufacturing

Ultrasonic welding has become a cornerstone of modern automotive production, offering unmatched speed, precision, and versatility. As technology continues to evolve, its role will only expand—driving innovation across vehicle design and manufacturing processes.